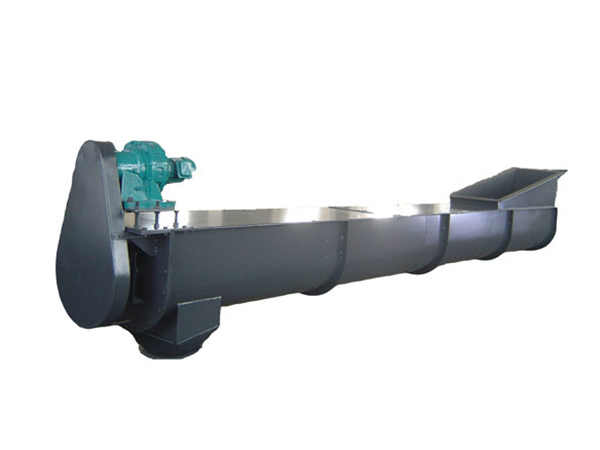

The LS series screw conveyor is designed according to the equivalent ISO1050 standard and manufactured in accordance with the JB81005 professional standard. Compared with the GX series screw conveyor, the head and tail bearing seats are moved outside the shell, and the middle suspension shaft can be interchanged with rolling (M1 method) or sliding (M2 method) structures, both of which are equipped with dust sealing devices. The discharge end is equipped with a cleaning device, and the inlet and outlet positions are arranged flexibly, with low overall noise and strong adaptability The machine is easy to operate and maintain, and the sealing components used are nylon and polytetrafluoroethylene resins, which have the characteristics of low resistance, good sealing, and wear resistance. There are several types of bearing materials for the sliding pads used, including cast copper, alloy wear-resistant cast iron, copper based graphite low oil lubricating pads, etc. The main technical parameters of the LS series screw conveyor are shown in the table below:

|

»úÆ÷ÐͺÅModel |

LS100 |

LS160 |

LS200 |

LS250 |

LS315 |

LS400 |

LS500 |

LS630 |

LS800 |

LS1000 |

|

ÂÝÐýÖ±¾¶Screw diameter(mm) |

100 |

160 |

200 |

250 |

315 |

400 |

500 |

630 |

800 |

1000 |

|

ÂݾàScrew pitch(mm) |

100 |

160 |

200 |

250 |

250 |

355 |

400 |

450 |

<500 |

560 |

|

תËÙSpeed(rmp) |

71-140 |

<56-112 |

50-100 |

45-90 |

45-90 |

36-71 |

32-63 |

25-50 |

20-40 |

16-32 |

|

ÊäËÍÁ¿Conveying capacity(m3/h) |

1.1-2.2 |

3.1-7 |

6.31-13 |

11-22 |

15-35 |

31-62 |

50-98 |

77-140 |

126-200 |

140-280 |

|

×¢£º±íÖеÄÊäËÍÁ¿°´Ìî³äϵy=0.45¿¼ÂÇ£¬Ñ¡ÐÍʱÇë¸ù¾Ý¾ßÌåÎïÁÏÑ¡È¡Ìî³äϵÊýyc¶ÔÊäËÍÁ¿½øÐÐÐÞÕý¡£ |

||||||||||

E-MAIL dtlyjx@aliyun.com

Contact: Manager cui